A Century of Florentine Leather

Now in its fourth generation, Misuri looks forward while safeguarding tradition.

Few cities in the word rival the signature scent of Florence, Italy.

An accord built on association and observation, it’s easy to summon the scentscape.

Florence smells of sun-swollen tomatoes on the vine, glowing green basil, the autumnal shades of Mediterranean shrubs like rosemary (its tips tinged by hearth flame), with a vertical sting of cypress sap and to match the trees from which they’ve fallen.

In early winter, peppercorn, hearth smoke, and the heady scent of freshly unearthed truffles hover overhead.

But at its heart, Florence smells like leather. A warm, sweet assault, instantly recognizable.

*This article is part of our ‘Crown Jewels of Florence’ series, where we go behind the scenes with real Florentines.

Leather craft has flourished in Florence since Medieval times.

Artisan guilds and approved practices, known as L'Arte degli Cuoiai e Galigai were established as early as the 13th century. To this day, Florentine leather maintains a reputation for quality and artistry.

Tannery—the transformation of raw animal hides into versatile and durable materials—takes its name from the tannins employed in the process.

Did you say tannins?

If the tannins sound familiar to the wine savvy readers out there, you’re on the right track.

Tannins exist throughout the plant world, often in skins, barks, and seed husks. They function as protection again pests and act as natural preservatives.

In wine, the seeds and skins exposed to macerating grapes lends wine a drying, snappy quality on the palate, especially in young wines.

Nebbiolo, Sagrantino, and Cabernet Sauvignon are great examples. These wines enjoy long vibrant lives thanks these same tannins.

For more on wine tannins, check out his video, from my series 21 Days to Wine.

Water is integral to tannery.

The rise of leather tannery in Florence is directly related to access to fresh and flowing water from the Arno River.

Tannery requires constant soaking and rinsing of the raw hides as they are disinfected, treated with lime to facilitate the removal of hair and flesh, and finally preserved with tannic-rich barks and mineral salts before being colored, oiled, sliced, and refined for use in commercial production.

The production of dyes requires hours of soaking to produce dyes from flowers, plants, barks and spices.

This is followed by the actual dying process.

The regular source of water streaming through the city of Florence led to a vibrant industry in leather craftsmanship, often centered in neighborhoods close to the river, principally Santa Croce, where Misuri’s original storefront still stands.

From Function to Fabulous Form

At the height of the Renaissance, new techniques like chiseling, gilding with gold leaf, and painting, transformed leather from utilitarian to a decorative art form.

As Florence surged as a hub of art and innovation, leather craftsmanship expanded to include accessories like gloves, shoes, and accessories.

Florence’s post-war fashion and design boom shined an international spotlight on Florentine leather, cementing the city’s heritage of sought-after craftsmanship.

The city embraced their signature skillset and encouraged young artisans to learn the trade.

For a fascinating glimpse into the history of leather production, check out the Scuola del Cuoio, located inside the Monastery of Santa Croce. It was established in the 1950s as a collaboration between the Friars of Santa Croce, and two of the city’s oldest leather artisan families to train young artisans and promote their wares.

Today the institute is still active, along with a delectable leather boutique.

Generational Artisanship

Even with the advent of modern technologies and synthetic treatments and dyes, traditional leather craft has been passed down through generations of Florentine families, several of whom are still in business today.

Alluring and ubiquitous, leather shops abound in Florence. Their dazzling selections of colorful bags and jackets and the intoxicating scent of vero cuio (genuine leather) can be overwhelming.

Misuri is a perfect place to start!

If You asked Me, I Could Write a Book

Cue the Dinah Washington version (best ever),

Misuri was established in 1906.

Manager and Creative Director, Carlotta, has so much to share about the business, she could write a book, she tells me excitedly.

In fact, she’s been collecting documents and material with that very goal in mind.

Meet Misuri: A Century of Leather Craft

I caught up with Carlotta who, along with her father Filippo, is currently carrying Misuri leather into its second century.

“We’re passionate about our craft, we love what we do, but ours is also a story of continually looking forward and evolving. We’ve sacrificed a lot over the years to keep the business afloat,” she says.

It begins with Cesare Misuri, a young bookbinder who had mastered the art of Florentine gold leaf imprints and adornments.

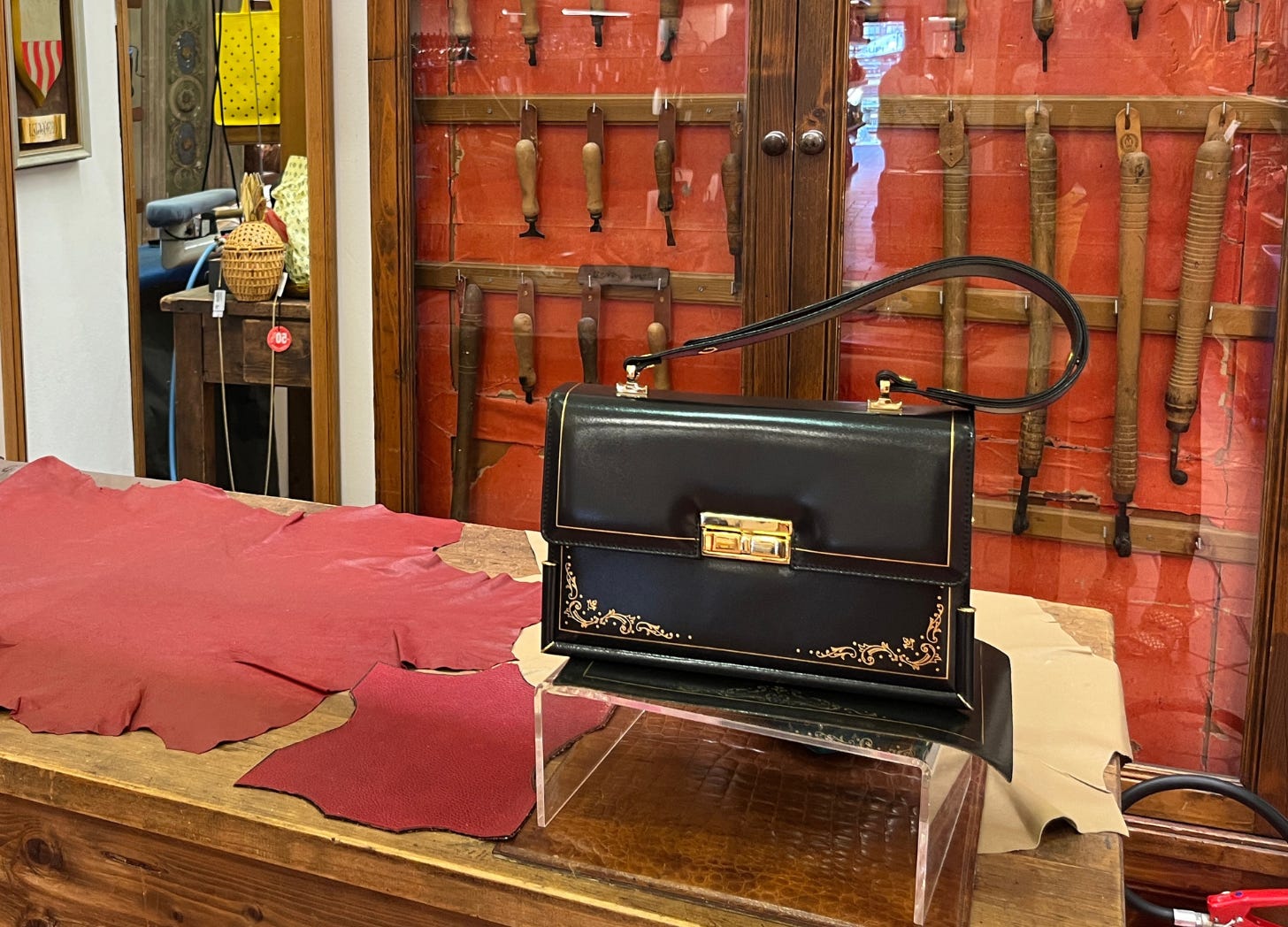

Eager to grow his skill set, he applies the technique to other leather pieces like decorative boxes and cases. His intricate designs and lend a luxurious quality to his work, and form the basis for the Misuri brand.

In 1906, he opens his laboratory on Piazza Santa Croce, at the heart of Florence’s leather district. In 1930 they open a storefront (where it still stands today), and before long, Misuri becomes synonymous with artisanal Florentine leather work.

From Father to Daughter

In 1943, at just 19 years old, Cesare Misuri’s daughter, Iolanda, takes the reins following his death.

WWII has ravaged the country, but Iolanda maintains her stealth commitment to the family business, pivoting production to suit American and English soldiers based in Florence and throughout Italy.

This act of survival would lead carry the Misuri name well beyond the Italian borders.

Nel 1948, Iolanda marries Daniel Quinn, an enterprising Englishman with global vision.

This infusion of international ambition combined with a boon of American tourism in the 1950s put Misuri on the map, literally and figuratively as the place to go for authentic, high quality Florentine leather.

From Floods of Tourists to Floods of Destruction

Like many of Florence’s enduring family businesses, the great flood of 1966 destroyed much of the factory store, but the Misuri family rebuilt and revitalized their business, more determined than ever.

Carlotta and Filippo’s family have been at the helm since the 1980s. they lovingly carry on Misuri’s namesake and heritage down to the detail. Carlotta keeps an eye on the future, while never losing sight of Misuri’s roots.

Her father, Filippo. handles the administrative side, whereas Carlotta oversees production of their latest creations, and the store itself.

“It’s funny to think about,” say Carlotta. During completely different eras, history repeats itself. Just like Cesare and Iolanda, today, it’s my father and I who forge onward.”

How has the leather business changed over the years?

In many ways, I’ve seen a positive change, says Carlotta. “Clients are more discerning than ever. They look for the finer details, higher quality, and unique, hand-made items.”

I ask her how Misuri stands out in a city swarming in leather shops.

“We differentiate ourselves by investing in research, constantly exploring new materials for jackets and handbags. The goal is to offer our clients an authentic shopping experience, and truly special products that represent the mark of Made in Italy, which is sadly vanishing.”

She continues, “Unfortunately, artisanal leatherwork is suffering a profound crisis moment. Many small, family-run artisan companies are closing. Our work is fundamental to preserving an enviable Florentine legacy.”

“It’s not simple, “she adds. “Tools like e-commerce and social media are time-consuming to implement and very competitive, yet they push us and increase our visibility. We’re doing our best. We’re really trying!”

Misuri is a fully immersive shopping experience, and a trip through history.

Tailoring and embossed lettering all happen on-site. It’s a look behind the curtain at one of Florence’s most revered and traditional trades, and a nod to founder Cesare’s original craft.

What’s a quintessential piece, something that embodies the essence of Misuri?

Carlotta doesn’t hesitate. “Our Kelly 1950 bag is our signature. It’s completely made by hand and impossible to replicate on at industrial scale. The workmanship, the panels, and stitching require expert hands, skilled fingers, and even antique tools.”

The bag was born in 1950, in collaboration with Dante Calonici (formerly of Gucci) and Cesare Misuri, and is still handmade using original techniques. The classic model is gilded with 22k gold, applied with heated brass as per Cesare's storied practice.

“The Kelly 1950 embodies beauty, uniqueness, and our passion for tradition,” says Carlotta. “In the store, you can watch an artisan at work, Sandrina, as she crafts every detail by hand. It takes at least eight hours—not consecutively—to complete. Each stage requires time, patience, and great experience.”

It’s not just a bag. It’s a distillation of over 115 years of Misuri’s history and encapsulates Florentine artisan excellence.

The Kelly 1950 hovers around the €1,000 price point.

For those looking to spend a bit less, while taking home an authentic piece, choose anything in the store that appeals to you, and have it hand embossed.

I opted for a coin purse and matching a carry-all in a perfect azure blue my mother loved. It’s almost too pretty to use.

Misuri

Piazza di Santa Croce, 20

TEL +39 055 240995

SITE | @misuri.firenze

This story is part of the Crown Jewels of Florence series.

To read more from Carlotta, and get her behind-the-scenes Florentine recommendations on where to shop, eat, and drink in Santa Croce, consider an upgraded subscription.